The Work of TAMMERLE

Carpentry. Design. Interior.

Since 1954, the planning, design, and production of furnishings in a wide variety of styles, materials, and color combinations has been at the core of our work.

Across three generations, a commitment to perfection has shaped the company’s understanding of quality – perfection as a lived principle.

Tradition. Perfection. Technology.

A heritage woodworking company with over 70 years of continuous and innovative development.

From solid craftsmanship training and constantly optimized machinery to light-accurate renderings based on time of day, and the integration of cutting-edge technologies like AI and VR – artificial intelligence and virtual 3D reality.

Details.

Detailing means understanding the whole in depth and completing every element with precision – a harmonious interplay of vision and dedication.

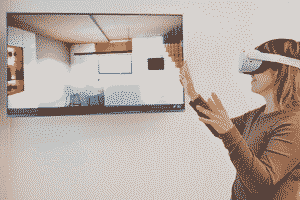

Technology.

With VR headsets, virtual spaces can be explored and realistically experienced even before production.

Interior.

Planning interiors means capturing the space as a whole – with materials, functions, and light.

3D visualizations allow producers and clients to experience and preview the final result in advance.

Perfection.

Perfection is not just a path to a solution but also a principle, a passion, and an attitude.

Carpentry.

The work of a carpenter today goes far beyond traditional woodworking.

Consulting, planning, understanding, designing, visualizing, crafting, tinkering, producing, and installing – with a wide variety of materials, surfaces, and finishes.

Design.

Design must be functional, with form giving function.

Form and function merge into one, unified in color, dimension, and proportion – with clean lines, reduced and harmonized.

History

Carpentry since 1954.

Initially working in rented spaces, the company has grown and developed continuously.

Each generation has contributed with its own skills and focus areas, shaping a holistic approach that has evolved over time.

3 Generations.

The first generation mastered the craft of carpentry and passed it on, the second invested and continuously developed the company, and the third expanded its standards through modern technologies such as renderings and 3D visualizations with VR headsets.

1954 Founding.

In 1954, at the age of 19, Alois Tammerle received his master craftsman certificate and founded Tammerle Carpentry.

1956 First projects.

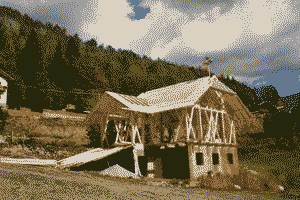

Alois takes on his first projects – in the village center of Afing, he builds the roof structure and covers the roof of the Reichhalter guesthouse – here together with Johann Lanznaster (Buchi Karl).

1960 Work.

In the early years, while still operating in rented spaces, the focus was on producing windows, doors, and traditional parlour furnishings with corner benches and tables.

1970 New Building.

In 1970, the first new building was constructed, combining the workshop and the family’s residence under one roof.

1975 Workshop & Family Home.

The workshop was located on the ground floor, while the two upper floors served as living space for the family.

1982 Planning.

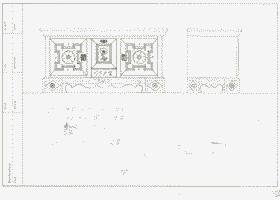

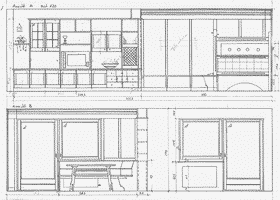

Before the era of computers, drawings were still made by hand—like this chest.

1983 Award.

During the Bolzano Fair, Robert Tammerle received the qualification diploma with outstanding results, ranking first in his year.

1984 Carpentry.

Alois Tammerle at work in spring 1984 – the first generation of the carpentry business.

1986 Timber Construction.

Occasionally, timber construction work was also carried out.

1987 Staircase.

A staircase, pre-assembled in the workshop.

1989 Certificate.

After completing his training at the State College in Rosenheim, Robert Tammerle is certified as a state-certified wood technician.

1991 Vehicle Fleet.

1990 wurde ein neues Lieferauto angeschafft, um die gefertigten Möbel zu transportieren. Hier im Jahr 1991 im Gadertal, St. Martin in Thurn.

1992 Aron.

During the 1980s and 1990s, Aron was the dog who greeted the employees first thing in the morning.

1994 Award.

Alois Tammerle received a certificate in recognition of 40 years of craftsmanship.

1994 Expansion.

In 1994, the company structure was expanded after Alois Tammerle’s sons, Robert and Walter, joined the business. The second generation began to make its mark.

1995 New Building.

The completed company structure following the 1995 expansion.

1996 Carpentry.

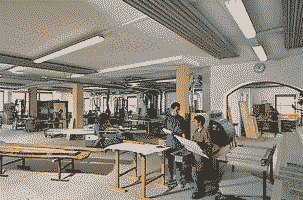

In the picture, Robert Tammerle is giving work instructions in the new production hall.

1997 Parlour Drawing.

Until the advent of computer-aided design, parlours were designed and drawn by hand.

1998 Work.

Walter Tammerle at the circular saw.

1999 Rex.

The German Shepherd is always around the workshop and in the timber storage.

2000 Work Preparation.

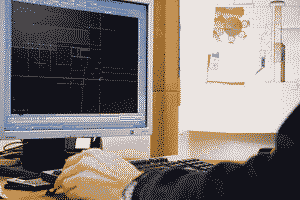

In 2000, the company transitioned its work preparation to computer-aided design.

2001 CNC.

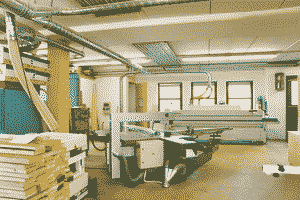

In 2001, Tammerle Carpentry became the first company on the Tschöggelberg to invest in a CNC machining center.

2005 Workshop.

The workshop machinery was continuously modernized, including the addition of a new circular saw and an edge banding machine.

2011 Technology.

Continuous improvement of the CNC programs made it possible to create new shapes.

2018 Carpentry & Design.

Die stetige Entwicklung führt dazu, dass Tischlerarbeiten zunehmend mit Design verschmelzen – das Verständnis wächst.

2022 State Prize.

Emil Tammerle received the Bavarian State Prize for outstanding technical and design achievements in craftsmanship – awarded for a chair 3D-printed from bio-compost.

2022 Award.

2022 Award.

Emil Tammerle completed his Bachelor's degree in Interior Architecture with top honors (grade 1.0) and received the Bavarian State Prize for his bachelor’s thesis.

2023 Visualization.

3D visualization and the associated customer consultation continue to improve.

Clients can now see exactly what their interior will look like before production begins – the third generation begins to show its influence.

2025 Federal Award.

The M5 chair makes bark beetle-infested spruce wood bendable thanks to a newly developed process.

Innovation, design, and regional focus provide a response to damaged wood issues and the challenges of climate change.

Considered Craftsmanship in the Spirit of Sustainability

Construction Sector & Buildings.

The construction sector is responsible for 39% of global CO2 emissions.

The production, sourcing, and processing of building materials account for 11% of these emissions.

Operating buildings through heating, cooling, and lighting contributes 28% to global CO2 emissions.

Transport & Internet.

The transport sector, including road, air, sea, and rail, accounts for 23% of global CO2 emissions.

The internet is responsible for 3.1% of global CO2 emissions, surpassing the emissions of the entire aviation sector.

Sustainability Label Level 2 – second-highest level in South Tyrol.

Tischlerei Tammerle has been awarded the South Tyrol Sustainability Label – Level 2. This certificate, representing the second-highest level, recognizes advanced commitment in the areas of ecology, economy, social responsibility, and corporate management – independently verified and internationally valid.

Considered Craftsmanship as a Holistic Approach.

Redefining sustainability: Considered craftsmanship means acting consciously and respecting nature and the environment in every field where the carpentry operates.

Kilometre-0 approach – Whether in manufacturing, reusing waste, generating energy, reducing consumption, or designing an energy-efficient website – always with awareness and the aim of minimizing environmental impact.

Location.

The location of Tammerle’s carpentry workshop allows for sourcing timber directly from the surrounding area.

All employees live within a 4-kilometre radius, making the site ecologically efficient thanks to short transport routes at every operational level – from material procurement to daily commuting.

Kilometre-0 Approach.

Sourcing materials locally and producing within their immediate surroundings allows CO2 emissions to be reduced throughout the entire value chain.

Energy is generated at the production site, and the manufacturing process is designed to emit as little CO2 as possible.

The kilometre-0 approach promotes the use of local materials, minimises transport routes, and reduces environmental impact – a key contribution to sustainable construction.

Photovoltaics.

A photovoltaic system installed on the carpentry workshop’s roof covers around 60% of the energy demand.

The operating schedule of the production machinery is optimised to maximise the use of self-generated electricity from the photovoltaic system.

E-Mobility.

An electric vehicle is part of the company’s fleet and, thanks to self-generated electricity, produces no CO2 emissions during customer consultations and service visits.

Energy-Efficient Website.

The TAMMERLE website has achieved a CO2 rating of A, making it more efficient than 85% of all websites worldwide.

With emissions of just 0.19 g of CO2 per page view, this is made possible in part by the use of sustainable energy – a reflection of considered craftsmanship in every area where the carpentry operates.

Wood.

Materials are sourced with a focus on regional, FSC- and PEFC-certified wood.

This approach minimises transport routes and consistently applies the kilometre-0 principle.

In-House Woodchip Production.

Producing woodchips in-house from wood waste and offcuts in the carpentry workshop creates a sustainable fuel that aligns with the kilometre-0 approach – from sourcing to on-site production.

These woodchips are used as eco-friendly fuel for the heating system and make a significant contribution to sustainable heat supply and the consistent implementation of the kilometre-0 principle.

Heating System.

The carpentry workshop heats its own facilities and five surrounding family homes using a Hargassner ECO HK boiler, which runs on woodchips made from in-house wood waste and offcuts.

The boiler operates efficiently with a yield of over 90% and complies with all EU emission standards.

Built-in dust filters and intelligent control systems optimise combustion and minimise emissions, ensuring a CO2-neutral and environmentally friendly heat supply.

Beetle Wood.

Rising temperatures and mild winters are causing an increase in bark beetle infestations.

Affected wood is often classified as 40% waste.

Damaged Wood Processing.

Beetle-infested wood is treated with steam to eliminate pests and preserve material stability.

The energy required for this process is sustainably supplied by the company’s own photovoltaic system.

Use of Beetle Wood.

Since 2023, regional beetle-infested wood that was previously classified as waste has been used for constructions, cover battens, and other wood products – in line with the kilometre-0 approach.